|

|

|

|

產(chǎn)品概述/Product overview |

1、ZN-C型是加長(zhǎng)筒體分離段���;

2�、為克服濃縮權(quán)頂二次蒸汽在末進(jìn)入冷凝器前被冷疑而返回罐內(nèi)的缺點(diǎn)�����。本設(shè)備將冷凝器改為斜臥式;

3���、為提高設(shè)備的生產(chǎn)能力�,本設(shè)備將濃縮罐夾套的加熱面積���,冷凝���、冷卻器的面積均有不同程度加大;

4���、為防止?jié)饪s罐出液管的死角,本產(chǎn)品中采用不銹鋼球形考克�����;

5�����、在濃縮罐下部設(shè)置了快開(kāi)式手孔���,以使清理罐內(nèi)殘液���,殘?jiān)?br />

6�、ZN-C型是將加熱夾套分兩段或三段����,當(dāng)液面低時(shí)關(guān)必閉上段加熱防止干壁。其底改為錐底便于排盡濃縮液�����。 |

1. ZN-C type is separation section of extended cylinder body

2. The condenser of this equipment is of inclined type in order to overcome disadvantages of secondary steam (on top part) condensation and flowing back to the concentrator before entering the condenser.

3. In order to improve production ability, heating area of jacket of the concentrator, area of condenser and cooler has been increased with different degrees.

4. Stainless steel ball cock is used to prevent dead corner in liquid outlet pipe of the concentrator

5. Quick-open hand hole is set at lower part of the concentrator to clear residual liquid and slag inside the concentrator.

6. The ZN-C type divides the heating jacket into two or three sections. When the liquid level is low, the upper section shall be heated to prevent dry wall forming. The bottom part shall be replaced with cone-shaped bottom to make it easier for concentration liquid discharging. |

|

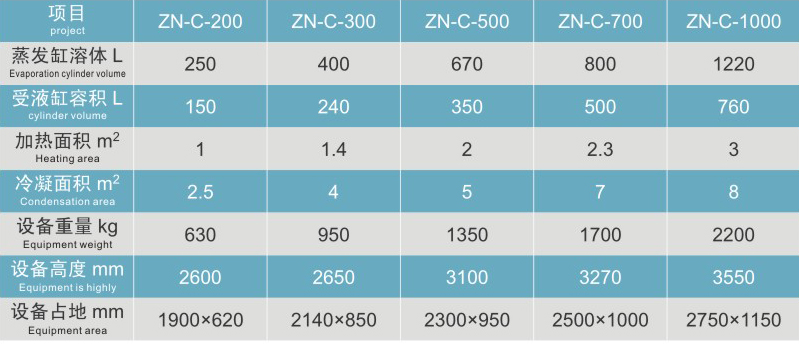

主要技術(shù)參數(shù)參考表/Reference table of main technical parameters |

|